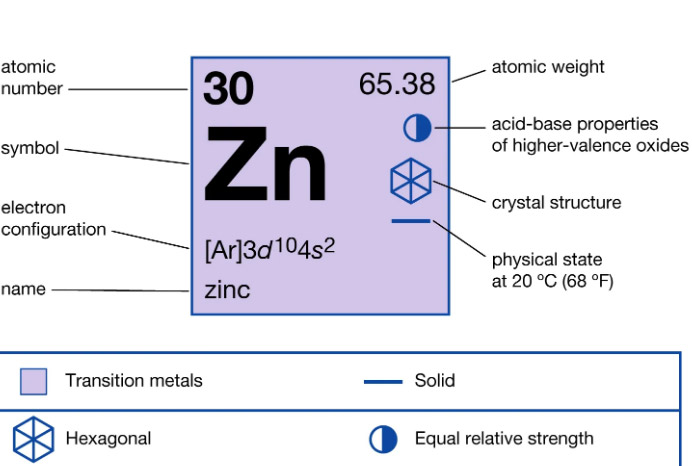

Zinc is one of the most versatile and widely used metals in modern industry. It’s a critical mineral that is used in a vast array of products, from construction materials to life-saving medical devices. But what is zinc and what makes it so special?

The Uses of Zinc

One of the most common uses of zinc is in galvanizing, a process where a protective layer of zinc is applied to iron or steel to prevent rusting. About half of the world’s zinc production goes into this process.

Zinc is also a key component in alloys such as brass (a combination of copper and zinc) and nickel silver, which are used in a variety of applications including musical instruments, jewelry, and coins.

In the automotive industry, zinc is used in die-casting to create precision parts. Its excellent casting ability makes it ideal for producing complex shapes with high precision.

Zinc oxide, a chemical compound of zinc, is used in the production of tires, rubber, ceramics, glass, cement, and paints. It also finds use in the pharmaceutical industry in products like ointments and creams, as well as in the personal care industry in products like sunscreen and anti-dandruff shampoos. It is also used in multi vitamins and supplements to boost immunity.

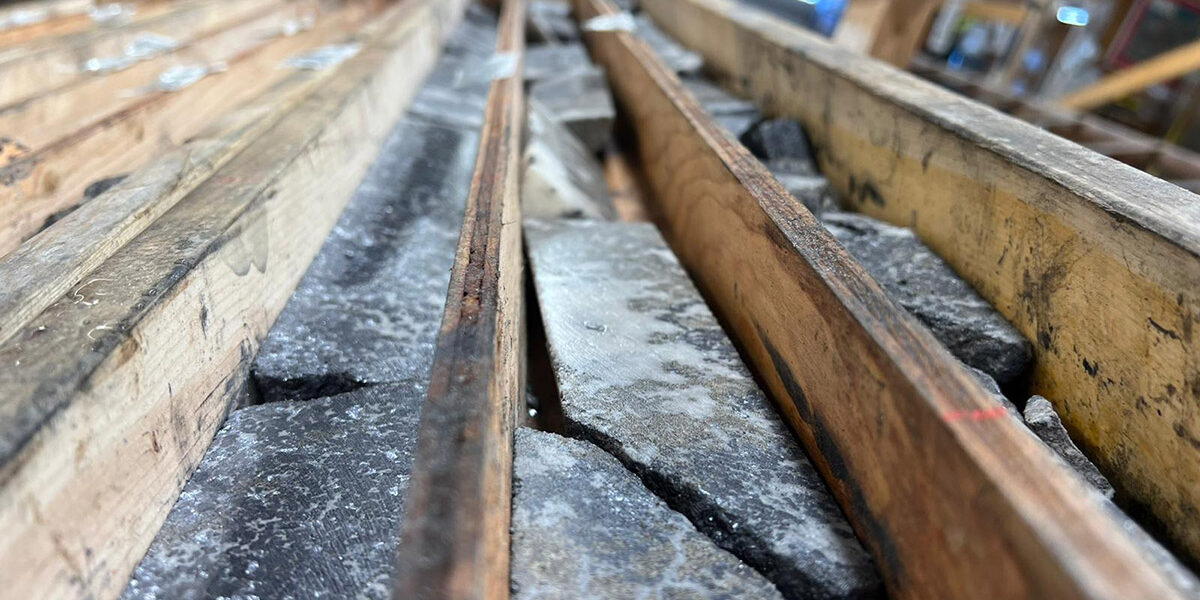

Extraction and Purification of Zinc

The production of zinc metal involves several stages. First, zinc minerals (such as sphalerite) that are present in typically polymetallic ores are mined and then crushed and ground. In the case of sphalerite bearing ores the zinc sulphide is concentrated by flotation processes at the mine site prior to shipping. The second transformation to extract zinc from the zinc concentrate is through a process called roasting, where it’s heated in air to produce zinc oxide. This is then reduced with carbon to obtain zinc metal.

To purify zinc, it’s often distilled. This process involves heating zinc to its boiling point and then condensing the vapor to obtain pure zinc.

Unique Properties and Benefits of Zinc

Zinc has several unique properties that make it particularly suitable for certain applications. It’s a relatively hard metal with a low melting point, making it ideal for die-casting. It’s also highly resistant to corrosion, which is why it’s so effective in galvanizing.

The benefits of using zinc in industry are numerous. It’s abundant, relatively inexpensive, and easy to work with. Its anti-corrosive properties and ability to bond well with other metals make it indispensable in many sectors.

One of 31 Critical Minerals

Zinc has been recognized as a critical mineral, fundamental to the transition towards a low-carbon economy. The World Economic Forum underscores its importance for developing a sustainable future. In addition, the U.S. Geological Survey’s 2022 list of critical minerals includes zinc, highlighting its significance in metallurgy.

In line with global recognition, Canada has identified zinc as one of its 31 critical minerals. This identification comes at a time when potential shortages of zinc are raising global concerns. The metal’s fundamental role in building a green energy future, similar to copper and nickel, makes it an indispensable resource.

Future of Zinc

Looking ahead, the role of zinc in the industrial sector is expected to grow. With the rise of sustainable practices, zinc’s recyclability is a major advantage. Furthermore, research into zinc-based batteries could revolutionize the energy storage sector.

In conclusion, zinc’s versatility and unique properties make it a vital player in modern industry. As we continue to innovate and develop new technologies, the importance of this remarkable metal will only increase.

Pine Point – Meeting the Need for Zinc

The Pine Point Project, located in Canada’s Northwest Territories, is a promising venture that looks to significantly aid global zinc production. The project is focused on exploring and developing the area’s abundant zinc-lead deposits. With its high mineral resource potential, Pine Point is expected to contribute substantially to the global zinc supply. Once in production it would rank as a top ten global producer.

For more information, visit us at www.pinepointmining.com.