On June 25, 2024, the 2024 Mineral Resource Estimate (MRE) Update for the Pine Point Project was released. This MRE will form the resource base for a feasibility study that officially began in late 2024. Cut-off grades are based on estimated long-term metal prices, mining costs, metal recoveries, concentrate transport, and smelter costs.

Highlights:

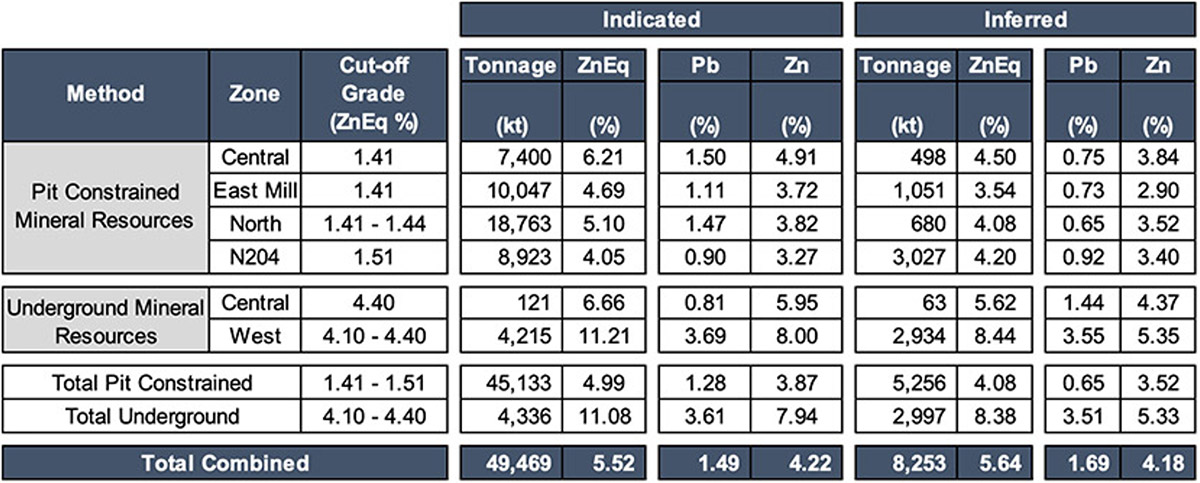

- Indicated Mineral Resources of 49.5Mt grading 4.22% zinc and 1.49% lead (5.52% Zinc Equivalent (ZnEq)) containing approximately 4.6 billion pounds of zinc and 1.6 billion pounds of lead in situ (undiluted)

- Inferred Mineral Resources of 8.3Mt grading 4.18% zinc and 1.69% lead (5.64% Zinc Equivalent (ZnEq)) containing approximately 0.7 billion pounds of zinc and 0.3 billion pounds of lead in situ (undiluted)

- Compared to the previous MRE, the conversion of Inferred Mineral Resources (see press release dated July 13, 2022) increased the tonnage of the current Indicated Mineral Resources by 214% with an associated decrease in the quantity of Inferred Mineral Resources

- Mineral Resources reported for the 2024 MRE used variable cut-off grades between 1.41% and 1.51% ZnEq for open pit resources and between 4.10% and 4.40% ZnEq for underground resources

- The project’s East Mill, Central, and North Zones now contain approximately 36.2Mt of Indicated Mineral Resources grading 5.22% ZnEq, or 3.2 billion pounds of zinc and 1.1 billion pounds of lead in situ

- New metallurgical test work is in progress. Previous metallurgical test work described in the 2022 PEA (see press release August 29, 2022) highlighted Pine Point as a potential producer of among the cleanest, high-grade zinc and lead concentrates globally. This adds value to the project as any and probably most smelter clients would want some Pine Point concentrate for blending purposes.

The 2024 MRE is divided into five geographic zones, each composed of one or more individual deposits.